This site was translated

by Globalink Weg translator

UNDERFLOOR HEATING UNDERTILE HEATING UNDER FLOOR TILE

Underfloor Heating Conservatory wintergarden

Heating technology Floor heating Heating engineering Building technology

Installation

Floor heating Electric floor heating Electrical floor heating Electric

thin-bed heating mats Tile heating Bathroom heating Thin-bed heating

Electric heating Parquet heating Laminate heating Foot heating mat Raychem

UnderFloor heating Anti-chill

heating

Not all electric floor

heating systems are the same

Electric floor heating

is safe, cheap and reliable

Heated floor

The low-cost heating systems for

taking the chill of the floor in the bathroom, kitchen, nursery or conservatory

(frost protection), with the brand-name thermostat from Eberle.

Electric floor heating for stone

floors, tiles, parquet or e.g. even beneath dry floors for renovation

of old buildings!

Thermofloor 2000 S &Thermofloor

S & Underfloor PV!!

| The Fliesenheizung:

or better

The Fliesentemperiersystem!

|

2 Standartbreiten 0,3m & 0,5m

with Schutzleiter

high quality

completely available with regulators & Fühlerschutzrohr

with Verlegeanleitung & current -

anschlussplan (very simply)! |

The Fussbodentemperiersystem, which offers you a very pleasant Wohnklima:

| Scopes: |

Use & advantages: |

Baths and kitchens

Verkaufsräume e.g. butchers

Offices

at slight Fussbodenaufbauhöhen

aesthetic reasons (no radiator)

Altbausanierung

Teilflächenheizung Sitzgruppen

Wintergartentemperierung (frost) |

Simple and fast transfer

fast temper (in the morning in the bath)

with timeswitchclock adjustable

extremely thin Heizmatten, 2mm thickly

surely, advantageously, maintenance-free

corresponds to international norms

warm feet cool head

pleasant Wohnklima

through high thermal radiation Temperaturabsenkung

possibly |

Verkaufspreisliste ' 99 in DM

All prices are inclusively the legal

value-added tax of 16%.

Thermofloor 2000 S:

| Thermofloor 2000 S 160 watt /m2; width 30 cm |

| Kind - No: |

Performance:

Watt/Stück |

Measured:

L x B in m |

Flat:

m2; |

Price

DM |

| TF2S16 |

160Watt |

3,3x0,3 |

1m2; |

174,00 |

| TF2S26 |

320Watt |

6,7x0,3 |

2m2; |

313,20 |

| TF2S36 |

480Watt |

10x0,3 |

3m2; |

440,80 |

| TF2S46 |

640Watt |

13,3x0,3 |

4m2; |

556,80 |

|

|

|

|

|

| Thermofloor 2000 S 130 watt /m2; width 50 cm |

| TF2S53 |

650Watt |

10x0,5 |

5m2; |

522,00 |

| TF2S63 |

780Watt |

12x0,5 |

6m2; |

614,80 |

| TF2S73 |

910Watt |

14x0,5 |

7m2; |

719,20 |

| TF2S83 |

1040Watt |

16x0,5 |

8m2; |

812,00 |

| TF2S93 |

1170Watt |

18x0,5 |

9m2; |

904,80 |

| Thermofloor 2000 S 100 watt /m2; width 50 cm |

| TF2S10 |

100Watt |

2x0,5 |

1m2; |

156,60 |

| TF2S20 |

200Watt |

4x0,5 |

2m2; |

220,40 |

| TF2S30 |

300Watt |

6x0,5 |

3m2; |

336,40 |

| TF2S40 |

400Watt |

8x0,5 |

4m2; |

417,60 |

| TF2S50 |

500Watt |

10x0,5 |

5m2; |

510,40 |

| TF2S60 |

600Watt |

12x0,5 |

6m2; |

591,60 |

Thermofloor S:

| Thermofloor S 160 watt /m2; width 50 cm |

| TFS1 |

160Watt |

2x0,5 |

1m2; |

116,00 |

| TFS2 |

320Watt |

4x0,5 |

2m2; |

185,60 |

| TFS3 |

480Watt |

6x0,5 |

3m2; |

255,20 |

| TFS4 |

640Watt |

8x0,5 |

4m2; |

324,80 |

| TFS5 |

800Watt |

10x0,5 |

5m2; |

394,40 |

| TFS6 |

960Watt |

12x0,5 |

6m2; |

464,00 |

Underfloor PV:

| Underfloor PV/4 160 watt /m2; width 30 cm |

| Kind - No: |

Performance:

Watt/Stück |

Measured:

L x B in m |

Flat:

m2; |

Price

DM |

| UPV 160 |

160Watt |

3,3x0,3 |

1m2; |

150,80 |

| UPV 320 |

320Watt |

6,7x0,3 |

2m2; |

220,40 |

| UPV 480 |

480Watt |

10x0,3 |

3m2; |

307,40 |

| UPV 640 |

640Watt |

13,3x0,3 |

4m2; |

400,20 |

|

|

|

|

|

| Underfloor PV/5 130 watt /m2; width 50 cm |

| UPV 530 |

650Watt |

10x0,5 |

5m2; |

406,00 |

| UPV 630 |

780Watt |

12x0,5 |

6m2; |

475,60 |

| UPV 730 |

910Watt |

14x0,5 |

7m2; |

556,80 |

| UPV 830 |

1040Watt |

16x0,5 |

8m2; |

632,20 |

| UPV 930 |

1170Watt |

18x0,5 |

9m2; |

696,00 |

| Underfloor PV/5 100 watt /m2; width 50 cm |

| UPV 100 |

100Watt |

2x0,5 |

1m2; |

116,00 |

| UPV 200 |

200Watt |

4x0,5 |

2m2; |

197,20 |

| UPV 300 |

300Watt |

6x0,5 |

3m2; |

255,20 |

| UPV 400 |

400Watt |

8x0,5 |

4m2; |

336,40 |

| UPV 500 |

500Watt |

10x0,5 |

5m2; |

406,00 |

| UPV 600 |

600Watt |

12x0,5 |

6m2; |

487,20 |

| Regulators & Installationsset |

|

|

|

Price: |

from 5 StückEinkauf-preis/ST. |

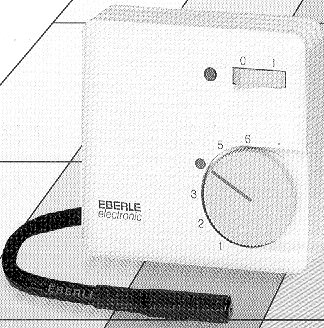

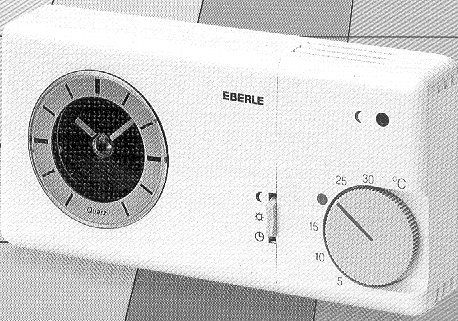

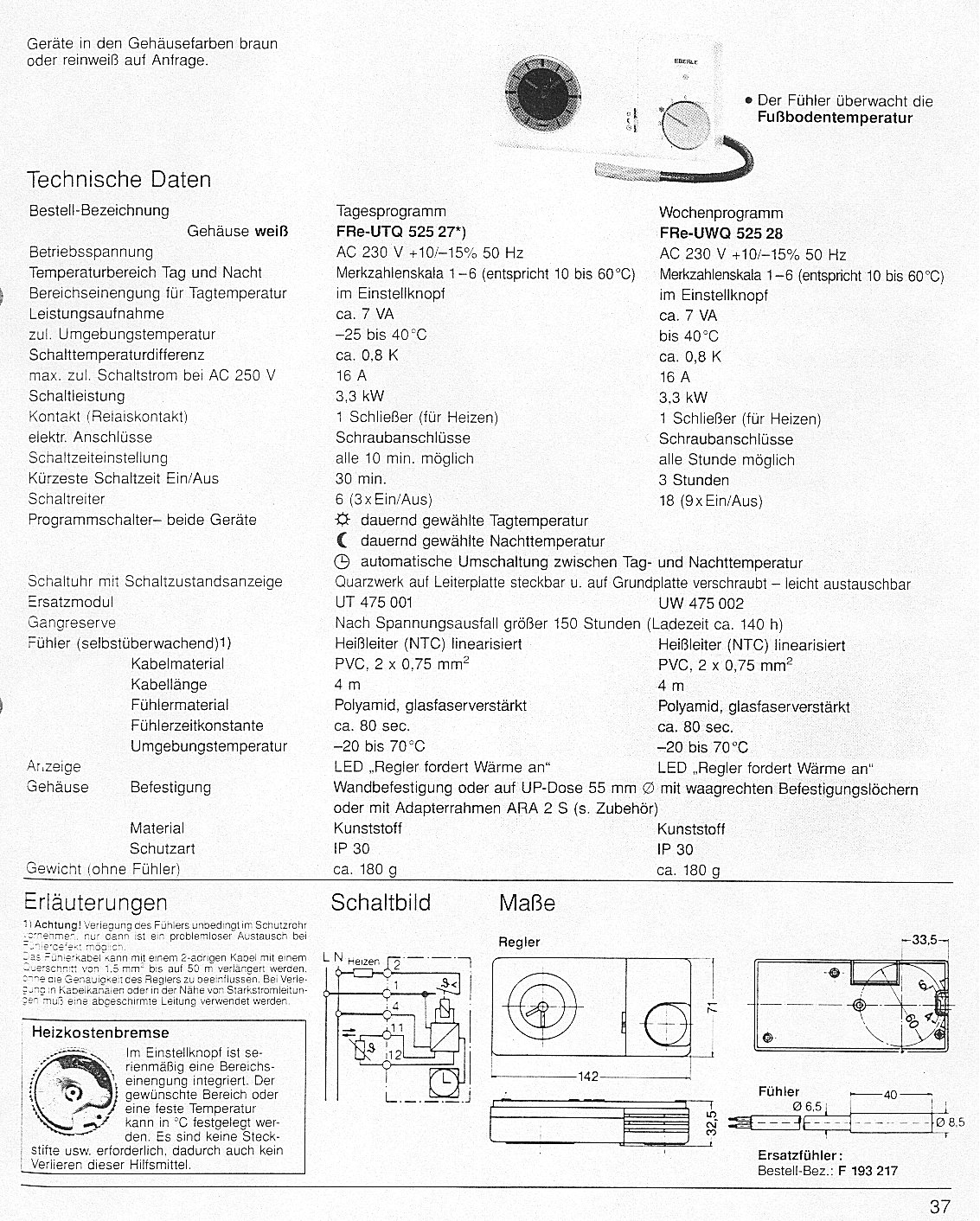

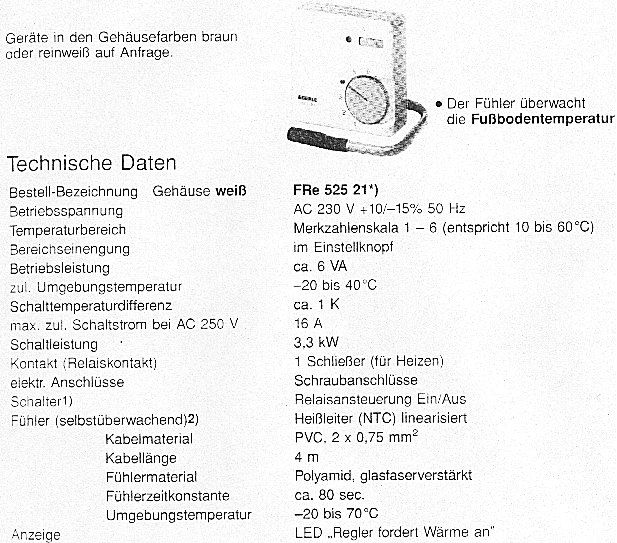

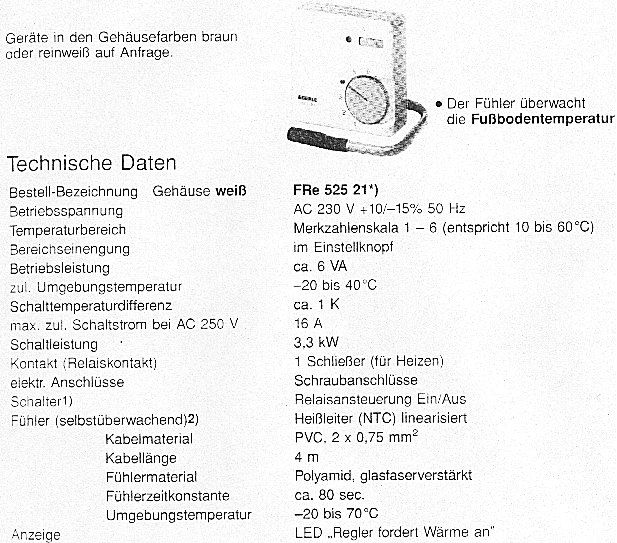

Eberle

EB52527 |

El. -Temperaturregler

with Bodenfühler

Tageszeitschaltuhr |

232, - |

220,40 |

Eberle

EB 52528 |

El - Thermostat

with Bodenfühler

Wochenzeitschaltuhr |

232, - |

220,40 |

Eberle

EB

52521 |

El - Thermostat

with Bodenfühler |

150,80 |

139,20 |

| INSTSET |

UP.Anschlussdose 100x100Fühlerschutzrohr

1m & Flexrohr |

46,40 |

30, - |

| Sale

and terms of delivery: |

The sale prices understand themselves inclusively the legal value-added

tax in an amount of presently 16%.

|

|

Lagerware 2 to 5 days, rare articles and larger numbers of pieces

up to 1 - 2 weeks.

In writing or per fax. To the Bestellblatt copy

DM incl. 16% MwST.

Per post plus postage and packaging. Attention: The delivery results

per C.O.D..

|

| Händleranfragen are desired!! |

Thermofloor S & Thermofloor 2000 S and Underfloor

PV

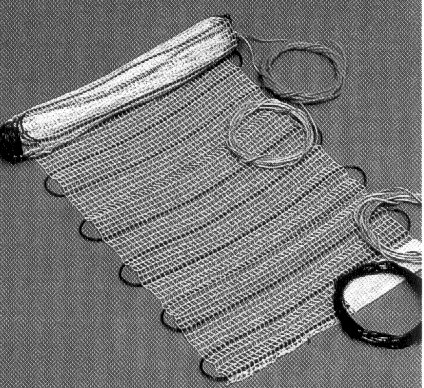

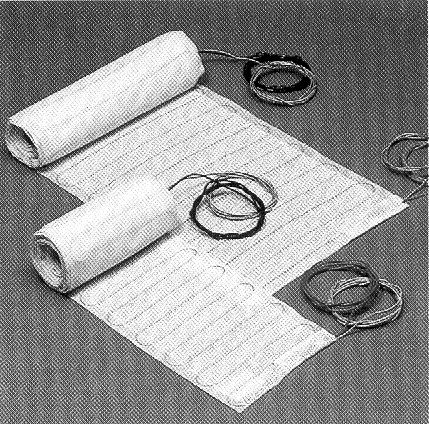

On a Textilgewebe is mäanderförmig the Heizleiter incensed. The

Heizleiter has only approx. 2mm diameters is feuchtigkeitsbeständig and

schutzisoliert, he/it is composed of a high-grade Widerstandslegierung.

At the beginning and at the end one each Heizmatte are 4m long Anschlussleitungen

(Neutralleiter/Schutzleiter, phase, Schutzleiter) from verzinntem coppers

appropriate. The Connecting - muffen are absolutely waterproof and zugentlastet

besides hochtemperaturbeständig. The Heizmatten leave themselves through

the hochflexible Textilgewebe without Aufwölbung smooth on the floor verlegen.Durch

the two Lieferformen the Heizmatte of 0,3m and 0,5m in different lengths

are different Quadratmetergrössen available. For the Beheizung of carpet,

PVC, parquet are anticipated the Leistungsklassen by 100 Watt/m2;, at tiles

and Steinbelägen should be used 160 Watt/m2; or 130 Watt/m2;. Thermofloor

S with 160 Watt/m2; finds at Wintergärten applications.

|

|

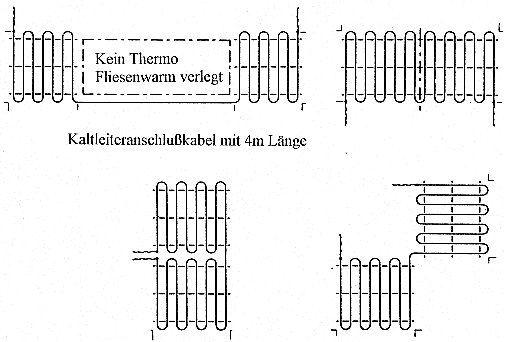

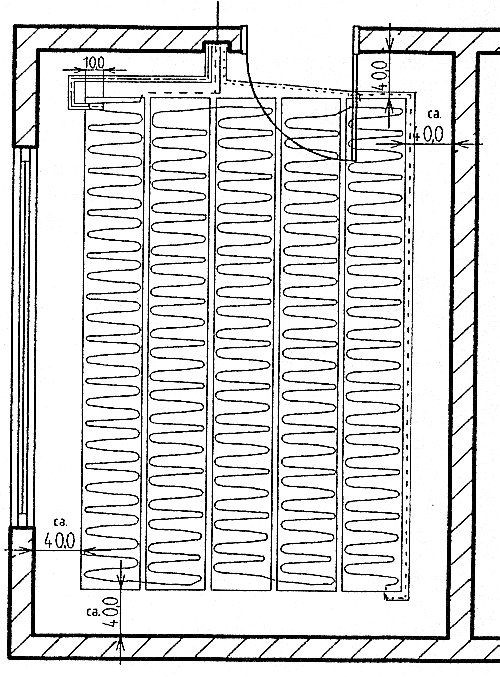

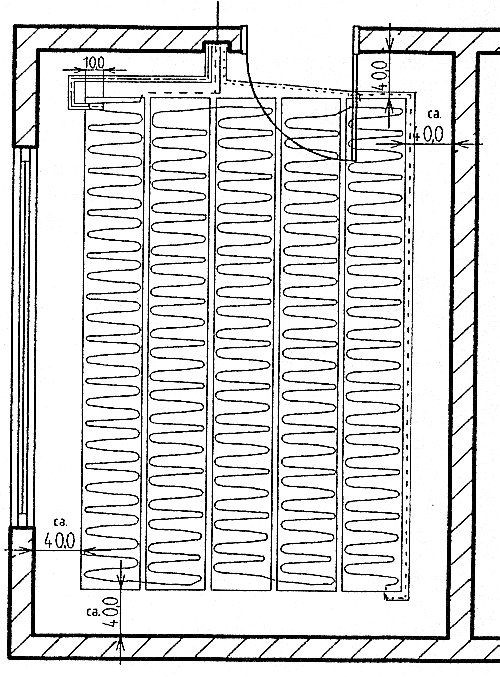

To

Thermofloor

Verlegebeispiele:

| On each smooth underground, like cement floor or as well as often

chipboard uses at Althaussanierung, on feuchtig - keitsbeständiger, can consider

the Heizmatte transfers werden.Bitte - " references for the setting and

transferring of ceramic tiles and disks on Holzspanplatten " - the trade

association of the German Fliesengewerbes. Also at Hotly - or Gussasphalt

must be considered, that these one temperature - beständigkeit of 80 C displays.

The Heizelemente are when transferring very flexiebel. Through the mäader

- förmig embarrassed Heizleiter can be reached a diversity and high variation

of the transfer. At the most different outlines is so an optimal adjustment

possibly (at two Verlegebreiten of 0,3m and 0,5m). |

|

|

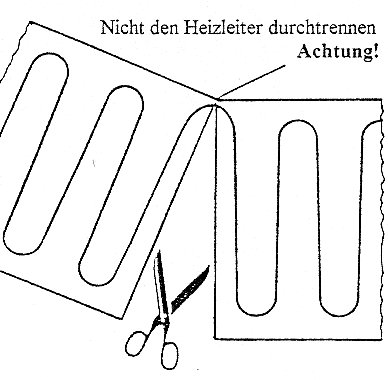

Through a cutting with an ordinary Haushaltsschere in the Textilgewebe,

the Heizelemente can be adjusted easily to the desired outline loudly Verlegeplan.

Now the antenna - schutzrohr must be transferred still in the floor, so

that the antenna can be introduced by the Heizungsanschlussdose in the Fühlerschutzrohr

and lie comes under the area of the heated plain to that. In the connection

covering - or Flexkleber (80C, by Knauf or PCI) can be begun with a temperaturbeständigen,

which compress tailored Heizmatte on the dry, smooth and dust-free floor

to verlegen.Heizmatte with Heizleiter after above in the Kleber, without that

the Heizleiter touch or lie one on the other. If the Heizmatte is completely

important, that is pasted in vollflächig (without Lufteinschlüsse). Oberbelag

with Flexkleber transfer, and/or Smoothed as mech. Protection at the transfer

of cork, PVC. etc. |

To

Thermofloor

The electric connection in the UP-Heizungsanschlussdose:

Only by an admitted expert the electric connection may be executed the

Thermofloor Heizbodens after the counting Vde - instructions and the Montageanweisung.

Also the Durchgangswiderstand (or the conductivity) must be measured during

the entire Montageablauf the Heizmatte. Through the constant measurement

the Durchgangswiderstand is guaranteed, that a damage is recognized the

Heizmatte immediately and can be exchanged the damaged Heizmatte against

a new and sound Heizmatte. At each mat the Ohmwert is to be entered in the

Revisionsplan and in the Leistungsschild (Verteilerkasten). Also a FI-Schutzschalter

with 30 mA should find in the Heizstromkreis application (in so far as not

already the whole apartment is equipped or at least the bathroom with a

Fi - protection), to guarantee especially in showers and baths the protection

and the safety against dangerous Körperströme. The Anschlussleitungen introduced

in the Unterputzdose the Heizmatte and the Temperaturfühlers are to be connected

after the below-mentioned circuit diagram. To a flawless connection the

Schutzleiters (gelb/grün) pay attention.

To

Thermofloor

The Temperaturregelung: EB

52521

| The Bodentemperatur is recorded with the Ntc - antenna and regulated

with the electronic thermostat EB 52521. The antenna of the regulator is

directly under the Heizebene, in the cement floor between the Heizleitern

in the Fühlerschutzrohr transfers. At the regulator the Bodentemperatur

can be discontinued the personal snugness - wunsch

or accordingly after Anwendungsfall (Wohnbereich or bathroom) . |

|

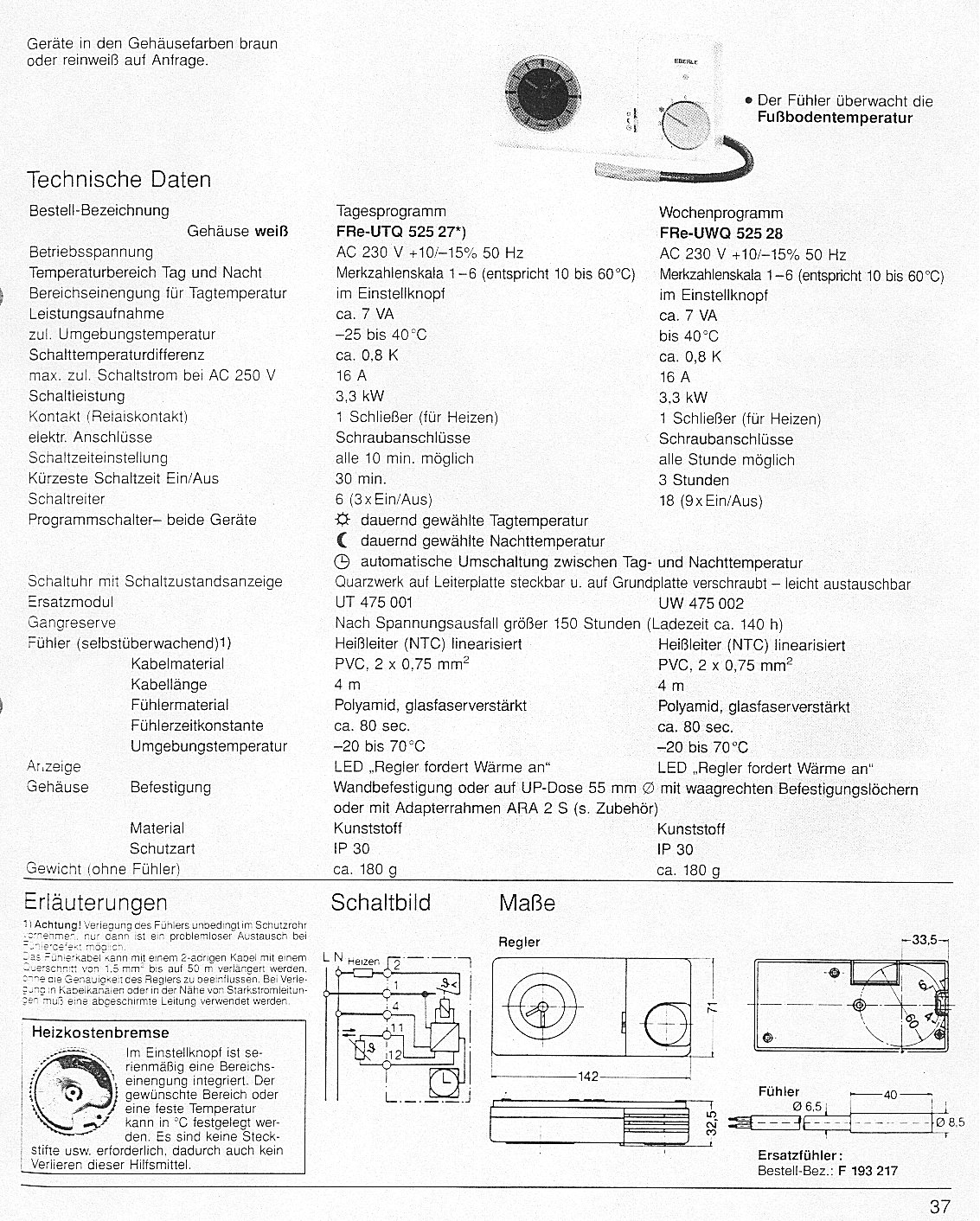

EB 52527

|

Without renunciation on snugness and comfort however especially

energy-saving because timewise controllable guarantees the regulation with

the special Uhrenthermostat EB 52527. The outlook should be undertaken so,

that 30 minutes before the Benutzungszeit results the automatic insertion

through the Elektronikregler. During or after the use is switched off again

automatically and not heat unnecessarily. Naturally can be switched off also

simply outside the discontinued times at the switch a - and. |

To

Thermofloor

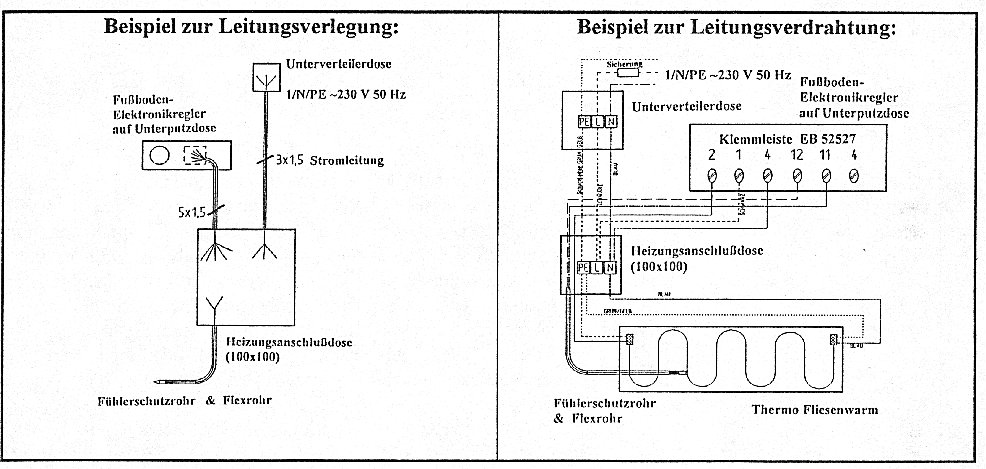

The Leitungsverlegung and Leitungsverdrahtung:

A comprehensive installation and instruction is attached each delivery.

Installation - and instruction:

To

the beginning:

1.Informationen for the user:

The order please carefully preserve and submit at Besitzwechsel the Nachbesitzer

or the new user. Thermofloor and Underfloor PV corresponds to the VDI. After

these determinations must be this order always available and will submit

at works at the heating the assembler to the perusal.

Only an admitted expert may execute the installation the Heizmatte.

After resulted installation and starting is to be submitted by the plumber

a Revisionsplan, which is to be preserved carefully with the installation

- and instruction. The Revisionsplan lists, at which places of the room

the Heizmatte transfers and the Fühlerschutzrohr was installed and at which

place the Leistungsschild appropriate ist.Im embarrassed area the Heizmatte

may be brought in no gedübelten screws for any Befestigungszwecke. In the

area of the walls a unbeheizte zone by approx. 50 cm is to be anticipated

width already in the planning, in so far as late closets with vollflächiger

should be found supporting surface there. Further covers e.g. through carpets

with more than 12mm thickness increase the temperatures in the floor and

must be avoided. The dates of performance the Heizbodens are noted by the

assembler at the Innentür of the electric distribution well visibly. To

the content

2. Betriebsfunktion:

A direct underfloor heating is The Heizbodens, which makes possible a quick

warming individual cold Gehbereiche e.g. in kitchens, baths, Saunabereichen

halls or Sitzgruppen. The Heizboden does not serve first of all the Raumheizung

(the required Heizleistung of the room is covered in the normal case by

an other Heizquelle), but only the tempering the cold Fussbodenbereiches.

The temperature is lifted according to outlook only around some Temperaturgrade,

so that the Heizboden consumes only the least time electric current and

is to be pursued thus very sparingly. In the necessity the entire performance

can be claimed also the Heizbodens, in that the regulator becomes according

to hochgestellt. The Heizboden is pasted directly on the cement floor and

sticks only in a 5mm to 10mm thick Klebeschicht and can submit therefore

quickly his warmth at the floor-covering and for a pleasant temperature

in the Fussbereich sorgen.Über an electronic Bodentemperaturregler results

the regulation the Heizbodens. In the Heizebene the antenna is installed

and compares the temperature discontinued at the regulator with the Bodentemperatur.

The Heizboden is switched off according to Wärmeanforderung and the Bodentemperatur

discontinued at the Drehknopf through the regulator a - and. Sonneneinstrahlung,

Wärmegewinn through persons, lighting or other Wärmequellen are recorded

through the regulator and considers. Also the regulator as Frostwächter.Der

serves regulators supervises itself personally, which means at Spannungsausfall,

Fühlerkurzschluss or Fühlerbruch switches off itself the regulation the Heizbodens

selbsständig. To

the content

3. service:

The service the Heizbodens limits itself to the outlook the desired Bodentemperatur

at the Drehknopf of the regulator. The temperature can be discontinued using

the Celsiusgradzahlen easily. The achievable Bodentemperaturen are from the

floor-covering (tiles or cork) and the insulation the cement floor dependent.

Read please also the operating instruction the Reglers.Einen especially energy-saving

organization can reach you through the application a Zeitschaltuhrreglers

(e.g. EB 52527). With this regulator the Heizboden can be switched off after

personal habits to certain times a - and. The Heizbeginn is to be chosen

approx. 30 min (according to Leistungsklasse of the Heizbodens) before the

Benutzungszeit and can be stopped also approx. 30 min before end the Benutzungsdauer.

To

the content

4. Maintenance and disturbance:

A maintenance of the heating is not necessary. In the disturbance you

examine, whether the regulator is discontinued for the heating. At day -

or weeks program, whether the Betriebszeit is discontinued correctly. Put

firmly whether the security or the FI-Schutzschalter have triggered. If no

warming is to ascertain inform you your assembler and submit Him/it the Revisionsplan.

To

the content

5. For the assembler:

The Montageanweisungen are to be considered at the installation.

These orders must be after counting Vde - determinations any time available

and will submit at works at the heating the plumber for the regard. For

that reason we ask you, which Revisionsplan along with this order to surrender

the consumer for the careful storage.

- Heizleiter after DIN owns The Flächenheizelement Thermofloor or

Underfloor PV VDE 0700 and can under observance relevant Installationsvorschriften

in the Innenbereich of living spaces, showers and bathrooms, indoor swimming

pools and damp and/or, wet rooms for the Temperierung of the floor are

installed.

- Only an expert may execute the installation and the connection the

Heizbodens as well as other electric Betriebsmittel. To it is the DIN VDE

0100, to consider part 520 A3.

- Special Installationsnormen count besides at:

- Duschräumen and bathrooms: DIN VDE 0100, part 701.

- Considered swimming pools: DIN VDE 0100, part 702.

- Damp and wet areas: DIN VDE 0100, part 737.

1. The Heizboden is determined using the plain and performance (Watt/m2;)

to be heated.

Verlegeplan in the Grundrissplan einzeichnen (Verlegebahnbreite consider

0,5m or 0,3m).

2. The Heizboden can on each smooth underground like feuchtigkeitsgeschützte

Holzspanplatten or simple cement floor are transferred.

3. attention: If the Heizbodens should be transferred on Heissasphalt,

must it

Heissasphalt approx. 80 C temperaturbeständig be.

4. In Sanitärräumen the plains must them for the installation of status

- Wc, bathtub,

Shower, ect. necessary have be left out. To leading materials must at

least 30mm

Stood off are held.

5. The Heizmatten under closets do not transfer.

6.Heizungsanschlussdose

outside of bath or WC set

(Wandfliesen complicate the accessibility).

7. Necessary plumbing and Leerrohre transfer (see

Anschlussplan).

8. Fühlerschutzrohr under heated acreage install and Flexrohr in Heizungsanschlussdose

introduce.

9. Heizelemente on them to beheitzende acreage explain and adjust.

Durchgangswiderstand, conductivity examine. Important: Under no circumstances

the Heizleiter the Heizmatte shorten.

The Heizmatte always as whole piece transfer.

Never the rolled up Heizmatte heat! Zerstörungsgefahr!!

10. Underground clean and pre-treat. There are allowed to do no sharp

or sharpen elevations

or deepens in the underground be available. The Heizmatte not with nails

or metallic object fasten.

11. At the transfer the Heizmatte these do not squeeze or crack. Not with

Zugbeanspruchung transfer.

12th Paid attention: Under no circumstances the Heizleiter the Heizmatte

cross.

13th Specially - Fliesenkleber (Flexkleber) use and with Zahnspachtel

5mm evenly

direct.

14. Never: The Heizmatte may not cross with Dehnungsfugen in the floor.

15. In the area the Heizmatte no gedübelten screws bring in.

16. The Heizmatte with the smooth Fliesseite after below in the Kleber

bring in and

easily press.

17. Kaltleiterenden and Schutzleiter in the Fliesenkleberbett to the Heizungsanschlussdose

lead and

once more Durchgangswiderstand conductivity examine.

18th Heizungsanschlussdose loudly plan wire.

19. Always as mech. Protection, which Heizmatte with a second layer

Spezialfliesenkleber (Flexkleber) 5mm carefully cover, (important hint,

Flexkleber a

- " little dünnflüssiger"anrühren, it must be ensured, that itself no

air bubbles or

Lufteinschlüsse in the Flexkleber and in the area the Heizmatte under

the tiles can form)

If Natursteinbelag tile or bring in in this Kleberbett, once more

Durchgangswiderstand conductivity examine. Would be the Heizmatte at the

transfer

if one damaged been could remove the Heizmatte now still and against one

undamaged Heizmatte exchange.

20. At the transfer of Parkett,Teppichboden, cork, PVC, ect. Kleberbett

with Glättscheibe

smooth.

21. After two days the erstemal carefully heat. (5 C/Tag)

22. At the transfer of parquet, carpeting, cork, PVC, ect. Undercoat to

it

According to Haftvermittlung the Herstellerangaben use.

23. Heated floor not with carpets the thicker than 12mm are covered (Wärmestaugefahr).

Vollflächige pieces of furniture may not be put on heated plains.

24. Users over the Fliesenheizung einweisen and Revisionsplan with Verlegeplan

submit.

In the electric distribution a reference place, (floor electrically heats.)

just as rooms indicate.

To the content

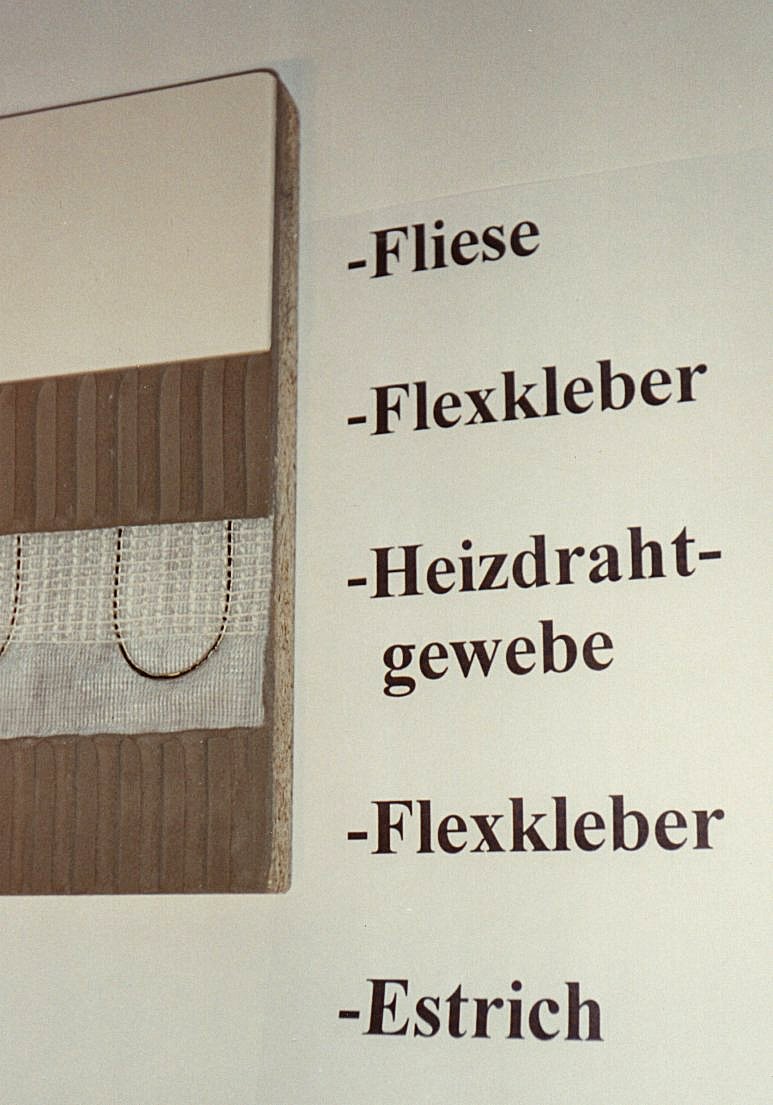

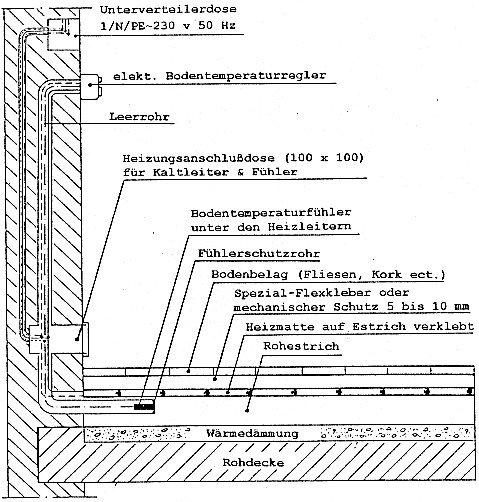

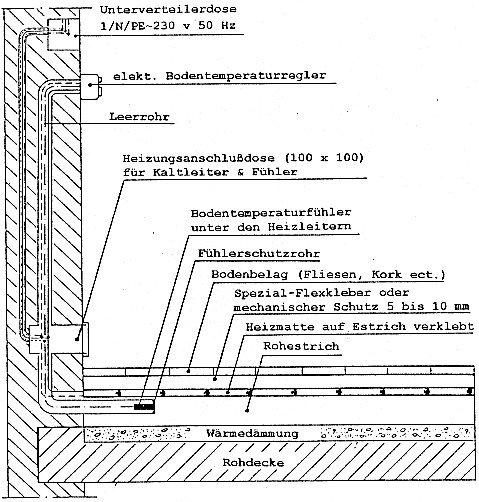

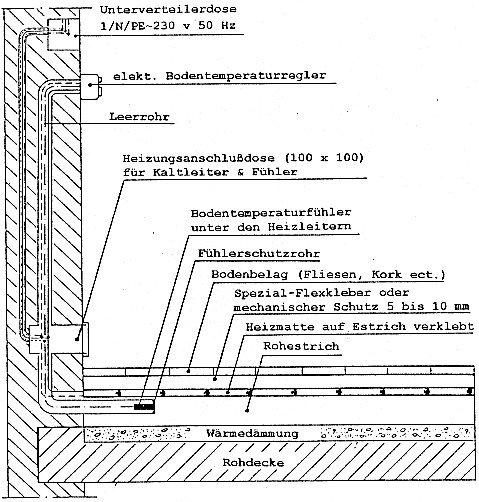

| 6. Schematic

construction the Heizbodens: |

7.

Example for Transfer and Revisionsplan: |

|

|

To

the content

8. It Transfer - and Revisionsplan draw:

Before the Heizmatte transferred will must be noted in the Revisionsplan

(outline) following points.

At which places in the room itself

- the Heizboden

- the Fussbodentemperaturfühler and the course the Fühlerschutzrohr

- the Kaltleiter (phase, Neutralleiter, Schutzleiter) the Heizmatte

find.

- In showers and bathrooms the plains of bathtubs must, Duschwannen,

status - Wc ect. if werden.Von left out leading materials min 30 mm stand

off.

- To walls a distance from 30 cm can be held to 50 cm (depending on

these plains later with vollflächigen pieces of furniture are covered).

After the installation the Revisionsplan is to be submitted the user

in any case for the careful storage.

Outline with Transfer - and Revisonsplan:

To

the content

9. preliminary treatment of the acreage to be heated:

First of all the surface the floor check, whether sharp or pointed elevations

or deepens tower from the floor, which the Heizmatte could damage. If that

should be the case, must to transfer these carefully removes werden.Vor

of the installation the Heizmatten is a Unterputzdose at a favorable place

(in the bath because of the tiles günstigerweise on the outside e.g. in the

passage), in which both the Kaltleiter as well as the Fühlerschutzrohr can

be introduced well. In the Unterputzdose an electric connection with 3x1,5

is to be put mm2; Anschlussleitungen. From the Unterputzdose to the place

at that the electronic Bodentemperaturregler be found should put a Anschlusskabel

with 5x1,5 mm2;.

Attention:

The Kaltleiter are to be introduced without extension in the Unterputzdose,

which Bodentemperaturfühler is to be transferred in a separate Fühlerschutzrohr

Ø 13 mm (at that best immediately antennas and Fühlerschutzrohr together

with each other transfer). The transfer has to result so, that the antenna

is found in the Fühlerschutzrohr directly under the area the later embarrassed

Heizboden in the cement floor (like in the Revisionsplan anticipated).

Kaltleiter the Heizboden and the antenna of the regulator may not be

transferred in the same Leerrohr.

The Bodenfühler of the regulator in the Fühlerschutzrohr introduce and

pay attention to it, that the end of the antenna in the Fühlerschutzrohr

at the following transfer in the area between two Heizleiter are used befindet.Sollte

an open Fühlerschutzrohr, so is to be locked this with a plug, that no

Fliesenkleber can penetrate itself into the reed.

The Fühleranschlussleitungen so transfer, that these cross the Heizleiter

neither nor touch. To

the content

10. Yield the Heizbodens:

With the Heizleiter after above the Heizmatte on the Verlegefäche, according

to the outline and Revisionsplan, yield. With a scissors the Stoffgewebe

can (attention: only the Stoffgewebe not the Heizleiter durchtrennen) are

cut through and are brought so the Heizmatte in the desired Verlegeform. Attention

important: Never the Heizleiter may be shortened the Heizmatte. The Heizleiter

at the durchtrennen the Textilgewebes do not damage.

At the durchtrennten place the Textilgewebes can be bent the Heizleiter

now carefully and are transferred parallel to the first path. The Heizleiter

however do not crack, which totals kleinst possible Biegeradius 20mm.

Also important:

The Heizbahnen the Heizmatte never one on the other transfer. Between

the Heizleitern must be at least a distance from 3cm available.

After this pattern the entire Verlegefläche is explained now with the

Heizmatte.

Attention warranty:

With a gauge the Ohmwert must be determined the Heizmatte (comparisons

with technical data) and in the Revisionsplan as well as in the Stromverteilung

are noted.

The Kaltleiter become, while the Heizmatte is pasted, in which Kleberbett

transfers to the Heizungsanschlussdose and introduced in the Heizungsanschlussdose

(the best in a separate Flexrohr, which leads from the wall - Estrichkante

in the Heizungsanschlussdose).

To

the content

11. Kleber for Heizmatte and Oberbelag:

| At the Verklebung the Heizmatte, the transfer of tiles as well as

as mechanical protection at Oberbelägen like carpets, PVC, cork, ect. if

Flexkleber suit, which are to maximum 80 C temperaturbeständig. |

1. Kleber for Heizmatten and ceramic disks (tiles) or Natursteinplatten:

PCI-Flexmörtel Specially - Fliesenkleber for balcony, terrace and underfloor

heating

Kleberbettdicke to maximum 5mm, from -20C to 80C, drying time approx.

4-5 hours.

Pci - Flexmörtel - Quickly Specially - Fliesenkleber for balcony, terrace

and underfloor heating

Kleberbettdicke to maximum 5mm, from -20C to 80C, drying time approx.

2-3 hours

or products of Knauf (ask you your Knauffachhändler)

2. Trittschutz at Oberbelägen, carpet, PVC, cork ect.

Around at the transfer of carpets, PVC, cork ect. a mechanical protection

to guarantee, must be covered the Heizmatte with a protective layer by

5 to 10 mm.

We recommend:

PCI-Periplan 10 to 10mm Schichtstärke

PCI-Periplan 20 to 20mm Schichtstärke

While the entire transfer examine with a gauge, whether the Heizmatte

is still conductive (Ohmwerte loudly technical data) To

the content

12th pasting the Heizmatten:

At the transfer of tiles and natural stones:

The instructions the Kleberherstellers are at the processing exact to

consider.

The Kleber is directed with a Zahnkelle (3-4 mm) on the floor. In this

Kleberbett the Heizmatte is inserted with the Heizleiter after above (smooth

page after below) and pressed with a Glättscheibe carefully. The durchgedrückten

Kleber carefully glattziehen. After that the upper side is covered the Heizmatte

once more with a layer of (Zahnspachtel 4-6 mm) Specially - Flexkleber, in

which directly the tiles or the natural stone is put. At the transfer on

it pay attention, that the Temperaturfühler comes between two Heizleitern

(loudly Revisionsplan) for the lying. The Kaltleiter just on the floor in

the Kleberbett to the Heizungsanschlussdose transfer and introduce through

a prepared Flexrohr in the Heizungsanschlussdose.

At the Verfugen of the tiles Flexfugenmasse use.

At the transfer of Oberbelägen like carpeting, PVC, cork, parquet:

After the Heizmatte was brought in described how above, and with a second

layer Specially - Flexkleber was covered, this mechanical protective layer

with the Glättscheibe must become cautious glattgezogen. werden. If necessary

can be covered after 24 hours these dry Kleberfläche once more, with it the

surface smooth and even becomes (PCI-Periplan). The Verarbeitungshinweise

of the respective fillers - maker are exact to consider.

The preliminary treatment of the surface hangs from the further application

the special Kleber

z. B. from cork, PVC, parquet or carpeting from. An undercoat for the

consolidation, Haftverbesserung should be anticipated in any case as underground

- preliminary treatment.

At the earliest after three days the Oberbeläge can be begun according

to damps in the underground with the transfer.

Only for underfloor heating suitable Oberbeläge use.

To consider are following values for the warmth - Leitwerte:

- -Wert = 0,14 W/(m.K) at parquet maximum 16mm thickly

- -Wert = 0,09 W/(m.K) at carpeting maximum 20mm thickly

- -Wert = 0,08 W/(m.K) at cork maximum 10mm thickly

- -Wert = 0,23 W/(m.K) at PVC maximum 10mm thickly

- -Wert = 1,00 W/(m.K) at tiles maximum 30mm thickly

- -Wert = 1,00 W/(m.K) at natural stone maximum 30mm thickly

Attention:

The Heizleiter may not touch the Kaltleiter and do not cross also.

While the entire transfer examine the Ohmwerte and compare with the

first measurement...

At a damage the Heizmatte is recognized this immediately and the damaged

Heizmatte can be exchanged against a sound Heizmatte.

The room mark, that the Handwerkerkollegen are informed about the electric

underfloor heating. To

the content

13th electrics connection:

Only by an admitted expert the electric connection may be executed the

Heizmatte after the counting Vde - instructions and the Montageanweisung.

The Heizboden must be connected electrically so, that allpolig totals

the Kontaktöffnungsweite at least 3mm of the net. Ls - Switch, securities

and marksman in the distributor are suitable Trennvorrichtungen. The instructions

the local EVU are to be considered. Also a FI-Schutzschalter with 30 mA

should find in the Heizstromkreis application, to guarantee especially in

showers and baths the protection and the safety against dangerous Körperströme

(normally extend it from if the apartment is furnished or at least the Badezimmerverteilung,

from which the Heizstrom originates, with a Fi - protection). The Heizbodens

according to the circuit diagrams connect. To a flawless connection the Schutzleiters

(gelb/grün) pay attention. There can be connected several Heizböden to an

electronic thermostat. It in the technical data indicated maximum Schaltstrom

and/or Schaltleistung is to be considered.

To

the content

14. Circuit diagrams:

z. B: Leitungsverlegung:

After the work: After the works finished is must be placed in the Verteilerschrank

a Leistungsschild with entered Ohmwert at well visible place. In the Revisionsplan

these Verteilerplatz note and the user this installation and instruction

for the careful storage übergebenInbetriebnahme: After 48 hours the Heizmatte

can be heated the first times carefully (5 C/Tag)

Leitungsverdrahtung: EB 52521 Leitungsverdrahtung: EB 52527 / 28

To

the content

Technical data: Messprotokoll:

| Kind - No: |

Performance:

Watt/Stück |

Measured:

L x B in m |

Flat:

m2; |

Ohmwert /

Heizmatte

approx. |

Tension:

1/N/PE |

DreiMesswerte:

per rooms:

Ohm |

| Thermofloor 2000 S or Underfloor PV/5 160 watt /m2; |

| TF2S16/UPV160 |

160 watt |

3,3x0,3 |

1 |

330 Ohm |

230V/50Hz |

|

| TF2S26/UPV260 |

320 watt |

6,7x0,3 |

2 |

165 Ohm |

230V/50Hz |

|

| TF2S36/UPV360 |

480 watt |

10,0x0,3 |

3 |

110 Ohm |

230V/50Hz |

|

| TF2S46/UPV460 |

640 watt |

13,3x0,3 |

4 |

82 Ohm |

230V/50Hz |

|

| TF2S56/UPV480 |

800 watt |

16,7x0,3 |

5 |

66 Ohm |

230V/50Hz |

|

| Thermofloor 2000 S or Underfloor PV/5 130 watt /m2; |

| TF2S53/UPV530 |

650 watt |

10x0,5 |

5 |

81 Ohm |

230V/50Hz |

|

| TF2S63/UPV630 |

780 watt |

12x0,5 |

6 |

68 Ohm |

230V/50Hz |

|

| TF2S73/UPV730 |

910 watt |

14x0,5 |

7 |

58 Ohm |

230V/50Hz |

|

| TF2S83/UPV830 |

1040Watt |

16x0,5 |

8 |

51 Ohm |

230V/50Hz |

|

| TF2S93/UPV930 |

1170Watt |

18x0,5 |

9 |

45 Ohm |

230V/50Hz |

|

| Thermofloor 2000 S or Underfloor PV/5 100 watt /m2; |

| TF2S10/UPV100 |

100 watt |

2x0,5 |

1 |

530 Ohm |

230V/50Hz |

|

| TF2S20/UPV200 |

200 watt |

4x0,5 |

2 |

264 Ohm |

230V/50Hz |

|

| TF2S30/UPV300 |

300 watt |

6x0,5 |

3 |

176 Ohm |

230V/50Hz |

|

| TF2S40/UPV400 |

400 watt |

8x0,5 |

4 |

132 Ohm |

230V/50Hz |

|

| TF2S50/UPV500 |

500 watt |

10x0,5 |

5 |

106 Ohm |

230V/50Hz |

|

| TF2S60/UPV600 |

600 watt |

12x0,5 |

6 |

88 Ohm |

230V/50Hz |

|

| Thermofloor S 160 watt /m2; |

| TFS116 |

160 watt |

2x0,5 |

1 |

330 Ohm |

230V/50Hz |

|

| TFS216 |

320 watt |

4x0,5 |

2 |

165 Ohm |

230V/50Hz |

|

| TFS316 |

480 watt |

6x0,5 |

3 |

110 Ohm |

230V/50Hz |

|

| TFS416 |

640 watt |

8x0,5 |

4 |

82 Ohm |

230V/50Hz |

|

| TFS516 |

800Watt |

10x0,5 |

5 |

66 Ohm |

230V/50Hz |

|

| TFS616 |

960Watt |

12x0,5 |

6 |

55 Ohm |

230V/50Hz |

|

Technical data:Eberle 52527 / 28

Back

Back

Bestellblatt:

To the order you click Produktnamen in the dunkelblauen

Anzeigefeld and choose on the right the Produktkategorie from choose you

the products through it - " orders " - Button. The products will print then

automatically in the Auswahlmenü - " Faxbestellung " - on the left below

transfer that you from and then fax or can send with the post.

| Kind - No: |

Performance:

Watt/Stück |

Measured:

Long x B

in m |

Flat:

m2; |

ordered piece: |

Preis:DM |

Gesamt:DM |

Thermofloor 2000 S or Underfloor PV 160 watt /m2; width 30 cm

| TF2S16/UPV160 |

160 watt |

3,3x0,3 |

1m2; |

|

|

|

| TF2S26/UPV260 |

320 watt |

6,7x0,3 |

2m2; |

|

|

|

| TF2S36/UPV360 |

480 watt |

10,0x0,3 |

3m2; |

|

|

|

| TF2S46/UPV460 |

640 watt |

13,3x0,3 |

4m2; |

|

|

|

|

800 watt |

16,7x0,3 |

5 m2; |

|

|

|

Thermofloor 2000 S or Underfloor PV 130 watt /m2; width 50 cm

| TF2S53/UPV530 |

650 watt |

10x0,5 |

5m2; |

|

|

|

| TF2S63/UPV630 |

780 watt |

12x0,5 |

6m2; |

|

|

|

| TF2S73/UPV730 |

910 watt |

14x0,5 |

7m2; |

|

|

|

| TF2S83/UPV830 |

1040Watt |

16x0,5 |

8m2; |

|

|

|

| TF2S93/UPV930 |

1170Watt |

18x0,5 |

9m2; |

|

|

|

Thermofloor 2000 S or Underfloor PV 100 watt /m2; width 50 cm

| TF2S10/UPV100 |

100 watt |

2x0,5 |

1m2; |

|

|

|

| TF2S20/UPV200 |

200 watt |

4x0,5 |

2m2; |

|

|

|

| TF2S30/UPV300 |

300 watt |

6x0,5 |

3m2; |

|

|

|

| TF2S40/UPV400 |

400 watt |

8x0,5 |

4m2; |

|

|

|

| TF2S50/UPV500 |

500 watt |

10x0,5 |

5m2; |

|

|

|

| TF2S60/UPV600 |

600 watt |

12x0,5 |

6m2; |

|

|

|

Thermofloor S 160 watt /m2; width 50 cm

| TFS1 |

160 watt |

2x0,5 |

1m2; |

|

|

|

| TFS2 |

320 watt |

4x0,5 |

2m2; |

|

|

|

| TFS3 |

480 watt |

6x0,5 |

3m2; |

|

|

|

| TFS4 |

640 watt |

8x0,5 |

4m2; |

|

|

|

| TFS5 |

800Watt |

10x0,5 |

5m2; |

|

|

|

| TFS6 |

960Watt |

12x0,5 |

6m2; |

|

|

|

Regulators & Installationsset for Thermofloor S & 2000S as well

as Underfloor PV

| EB 52527 |

El. -Temperaturregler with Bodenfühler

Tageszeitschaltuhr |

|

|

|

| EB 52528 |

El - Thermostat with Bodenfühler

Wochenzeitschaltuhr |

|

|

|

| EB 52521 |

El - Thermostat with Bodenfühler |

|

|

|

| Instset |

UP.Anschlussdose 100x100

Fühlerschutzrohr 1m & 2x Flexrohr |

|

|

|

Address or stamps with signature:

Endpreis: |

Fliesenheizung Elektroheizung electric

Wärmeboden floor heating system Heizboden Heizmatten heat warm bath kitchen

Kinderzimmer tiles stone floor cold feet Trockenboden Altbausanierung Ferkelaufzucht

Fliesenkleber Eberle Tekmar Termostat

electric underfloor heating Fliesenheizung

floor heating system Heizmatten Wärmeboden Badheizung Temperierung Speicherheizung

bath tiles Elektroheizung Flächenheizung Wintergarten frostschutz Eberle

Heizboden Dünnbrettheizmatten Altbausanierung Trockenboden warmth cold feet

Fuesse parquet Fliesenkleber Bodentemperierelemente 48V renovating Zeitschaltuhr

Fliesenheizung Elektroheizung electric

Wärmeboden floor heating system Heizboden Heizmatten heat warm bath kitchen

Kinderzimmer tiles stone floor cold feet Trockenboden

Altbausanierung Ferkelaufzucht Fliesenkleber

Eberle Tekmar thermostat Wochenzeitschaltuhr

electric underfloor heating Fliesenheizung

floor heating system Heizmatten Wärmeboden Badheizung Temperierung Speicherheizung

bath tiles Elektroheizung Flächenheizung Wintergarten

frostschutz Eberle Heizboden Dünnbrettheizmatten

Altbausanierung Trockenboden warmth cold feet Fuesse parquet Fliesenkleber

Bodentemperierelemente 48V renovating Zeitschaltuhr warm floor Heizleitung

floor-covering Badfussboden bad fliesenheizung elektroheizung tile Tageszeitschaltuhr

Raumheizung Thermo Fliesenwarm electronically Fussbodenfühler floor of

warm warms feet Fuesse planning elekto Direktheizung Zusatzheizung

Tageszeitschaltuhr Raumheizung Thermo

Fliesenwarm electronically Fussbodenfühler

Fliesenheizung Elektroheizung electric

Wärmeboden floor heating system Heizboden Heizmatten heat warm bath kitchen

Kinderzimmer tiles stone floor cold feet Trockenboden

Altbausanierung Ferkelaufzucht Fliesenkleber

Eberle Tekmar thermostat Wochenzeitschaltuhr

electric underfloor heating Fliesenheizung

floor heating system Heizmatten Wärmeboden Badheizung Temperierung Speicherheizung

bath tiles Elektroheizung Flächenheizung Wintergarten

frostschutz Eberle Heizboden Dünnbrettheizmatten

Altbausanierung Trockenboden warmth cold feet Fuesse parquet Fliesenkleber

Bodentemperierelemente 48V renovating Zeitschaltuhr

Cabeltherm Unitherm Flexel ThermoVlies

plus BET bet 2000 ElektroTherm Bauerhin Halmburger comfortfloor Dynatherm

Heizfolie Heizteppich Comfortfloor Sucotherm

Technical

data:

To

the Bestellblatt

Installation - and instruction:

To

the beginning:

1.Informationen for the user:

The order please carefully preserve and submit at Besitzwechsel the Nachbesitzer

or the new user. Thermofloor and Underfloor PV corresponds to the VDI. After

these determinations must be this order always available and will submit

at works at the heating the assembler to the perusal.

Only an admitted expert may execute the installation the Heizmatte.

After resulted installation and starting is to be submitted by the plumber

a Revisionsplan, which is to be preserved carefully with the installation

- and instruction. The Revisionsplan lists, at which places of the room

the Heizmatte transfers and the Fühlerschutzrohr was installed and at which

place the Leistungsschild appropriate ist.Im embarrassed area the Heizmatte

may be brought in no gedübelten screws for any Befestigungszwecke. In the

area of the walls a unbeheizte zone by approx. 50 cm is to be anticipated

width already in the planning, in so far as late closets with vollflächiger

should be found supporting surface there. Further covers e.g. through carpets

with more than 12mm thickness increase the temperatures in the floor and

must be avoided. The dates of performance the Heizbodens are noted by the

assembler at the Innentür of the electric distribution well visibly. To

the content

2. Betriebsfunktion:

A direct underfloor heating is The Heizbodens, which makes possible a quick

warming individual cold Gehbereiche e.g. in kitchens, baths, Saunabereichen

halls or Sitzgruppen. The Heizboden does not serve first of all the Raumheizung

(the required Heizleistung of the room is covered in the normal case by

an other Heizquelle), but only the tempering the cold Fussbodenbereiches.

The temperature is lifted according to outlook only around some Temperaturgrade,

so that the Heizboden consumes only the least time electric current and

is to be pursued thus very sparingly. In the necessity the entire performance

can be claimed also the Heizbodens, in that the regulator becomes according

to hochgestellt. The Heizboden is pasted directly on the cement floor and

sticks only in a 5mm to 10mm thick Klebeschicht and can submit therefore

quickly his warmth at the floor-covering and for a pleasant temperature

in the Fussbereich sorgen.Über an electronic Bodentemperaturregler results

the regulation the Heizbodens. In the Heizebene the antenna is installed

and compares the temperature discontinued at the regulator with the Bodentemperatur.

The Heizboden is switched off according to Wärmeanforderung and the Bodentemperatur

discontinued at the Drehknopf through the regulator a - and. Sonneneinstrahlung,

Wärmegewinn through persons, lighting or other Wärmequellen are recorded

through the regulator and considers. Also the regulator as Frostwächter.Der

serves regulators supervises itself personally, which means at Spannungsausfall,

Fühlerkurzschluss or Fühlerbruch switches off itself the regulation the Heizbodens

selbsständig. To

the content

3. service:

The service the Heizbodens limits itself to the outlook the desired Bodentemperatur

at the Drehknopf of the regulator. The temperature can be discontinued using

the Celsiusgradzahlen easily. The achievable Bodentemperaturen are from the

floor-covering (tiles or cork) and the insulation the cement floor dependent.

Read please also the operating instruction the Reglers.Einen especially energy-saving

organization can reach you through the application a Zeitschaltuhrreglers

(e.g. EB 52527). With this regulator the Heizboden can be switched off after

personal habits to certain times a - and. The Heizbeginn is to be chosen

approx. 30 min (according to Leistungsklasse of the Heizbodens) before the

Benutzungszeit and can be stopped also approx. 30 min before end the Benutzungsdauer.

To

the content

4. Maintenance and disturbance:

A maintenance of the heating is not necessary. In the disturbance you

examine, whether the regulator is discontinued for the heating. At day -

or weeks program, whether the Betriebszeit is discontinued correctly. Put

firmly whether the security or the FI-Schutzschalter have triggered. If no

warming is to ascertain inform you your assembler and submit Him/it the Revisionsplan.

To

the content

5. For the assembler:

The Montageanweisungen are to be considered at the installation.

These orders must be after counting Vde - determinations any time available

and will submit at works at the heating the plumber for the regard. For

that reason we ask you, which Revisionsplan along with this order to surrender

the consumer for the careful storage.

- Heizleiter after DIN owns The Flächenheizelement Thermofloor or

Underfloor PV VDE 0700 and can under observance relevant Installationsvorschriften

in the Innenbereich of living spaces, showers and bathrooms, indoor swimming

pools and damp and/or, wet rooms for the Temperierung of the floor are

installed.

- Only an expert may execute the installation and the connection the

Heizbodens as well as other electric Betriebsmittel. To it is the DIN VDE

0100, to consider part 520 A3.

- Special Installationsnormen count besides at:

- Duschräumen and bathrooms: DIN VDE 0100, part 701.

- Considered swimming pools: DIN VDE 0100, part 702.

- Damp and wet areas: DIN VDE 0100, part 737.

1. The Heizboden is determined using the plain and performance (Watt/m2;)

to be heated.

Verlegeplan in the Grundrissplan einzeichnen (Verlegebahnbreite consider

0,5m or 0,3m).

2. The Heizboden can on each smooth underground like feuchtigkeitsgeschützte

Holzspanplatten or simple cement floor are transferred.

3. attention: If the Heizbodens should be transferred on Heissasphalt,

must it

Heissasphalt approx. 80 C temperaturbeständig be.

4. In Sanitärräumen the plains must them for the installation of status

- Wc, bathtub,

Shower, ect. necessary have be left out. To leading materials must at

least 30mm

Stood off are held.

5. The Heizmatten under closets do not transfer.

6.Heizungsanschlussdose

outside of bath or WC set

(Wandfliesen complicate the accessibility).

7. Necessary plumbing and Leerrohre transfer (see

Anschlussplan).

8. Fühlerschutzrohr under heated acreage install and Flexrohr in Heizungsanschlussdose

introduce.

9. Heizelemente on them to beheitzende acreage explain and adjust.

Durchgangswiderstand, conductivity examine. Important: Under no circumstances

the Heizleiter the Heizmatte shorten.

The Heizmatte always as whole piece transfer.

Never the rolled up Heizmatte heat! Zerstörungsgefahr!!

10. Underground clean and pre-treat. There are allowed to do no sharp

or sharpen elevations

or deepens in the underground be available. The Heizmatte not with nails

or metallic object fasten.

11. At the transfer the Heizmatte these do not squeeze or crack. Not with

Zugbeanspruchung transfer.

12th Paid attention: Under no circumstances the Heizleiter the Heizmatte

cross.

13th Specially - Fliesenkleber (Flexkleber) use and with Zahnspachtel

5mm evenly

direct.

14. Never: The Heizmatte may not cross with Dehnungsfugen in the floor.

15. In the area the Heizmatte no gedübelten screws bring in.

16. The Heizmatte with the smooth Fliesseite after below in the Kleber

bring in and

easily press.

17. Kaltleiterenden and Schutzleiter in the Fliesenkleberbett to the Heizungsanschlussdose

lead and

once more Durchgangswiderstand conductivity examine.

18th Heizungsanschlussdose loudly plan wire.

19. Always as mech. Protection, which Heizmatte with a second layer

Spezialfliesenkleber (Flexkleber) 5mm carefully cover, (important hint,

Flexkleber a

- " little dünnflüssiger"anrühren, it must be ensured, that itself no

air bubbles or

Lufteinschlüsse in the Flexkleber and in the area the Heizmatte under

the tiles can form)

If Natursteinbelag tile or bring in in this Kleberbett, once more

Durchgangswiderstand conductivity examine. Would be the Heizmatte at the

transfer

if one damaged been could remove the Heizmatte now still and against one

undamaged Heizmatte exchange.

20. At the transfer of Parkett,Teppichboden, cork, PVC, ect. Kleberbett

with Glättscheibe

smooth.

21. After two days the erstemal carefully heat. (5 C/Tag)

22. At the transfer of parquet, carpeting, cork, PVC, ect. Undercoat to

it

According to Haftvermittlung the Herstellerangaben use.

23. Heated floor not with carpets the thicker than 12mm are covered (Wärmestaugefahr).

Vollflächige pieces of furniture may not be put on heated plains.

24. Users over the Fliesenheizung einweisen and Revisionsplan with Verlegeplan

submit.

In the electric distribution a reference place, (floor electrically heats.)

just as rooms indicate.

To the content

| 6. Schematic

construction the Heizbodens: |

7.

Example for Transfer and Revisionsplan: |

|

|

To

the content

8. It Transfer - and Revisionsplan draw:

Before the Heizmatte transferred will must be noted in the Revisionsplan

(outline) following points.

At which places in the room itself

- the Heizboden

- the Fussbodentemperaturfühler and the course the Fühlerschutzrohr

- the Kaltleiter (phase, Neutralleiter, Schutzleiter) the Heizmatte

find.

- In showers and bathrooms the plains of bathtubs must, Duschwannen,

status - Wc ect. if werden.Von left out leading materials min 30 mm stand

off.

- To walls a distance from 30 cm can be held to 50 cm (depending on

these plains later with vollflächigen pieces of furniture are covered).

After the installation the Revisionsplan is to be submitted the user

in any case for the careful storage.

Outline with Transfer - and Revisonsplan:

To

the content

9. preliminary treatment of the acreage to be heated:

First of all the surface the floor check, whether sharp or pointed elevations

or deepens tower from the floor, which the Heizmatte could damage. If that

should be the case, must to transfer these carefully removes werden.Vor

of the installation the Heizmatten is a Unterputzdose at a favorable place

(in the bath because of the tiles günstigerweise on the outside e.g. in the

passage), in which both the Kaltleiter as well as the Fühlerschutzrohr can

be introduced well. In the Unterputzdose an electric connection with 3x1,5

is to be put mm2; Anschlussleitungen. From the Unterputzdose to the place

at that the electronic Bodentemperaturregler be found should put a Anschlusskabel

with 5x1,5 mm2;.

Attention:

The Kaltleiter are to be introduced without extension in the Unterputzdose,

which Bodentemperaturfühler is to be transferred in a separate Fühlerschutzrohr

Ø 13 mm (at that best immediately antennas and Fühlerschutzrohr together

with each other transfer). The transfer has to result so, that the antenna

is found in the Fühlerschutzrohr directly under the area the later embarrassed

Heizboden in the cement floor (like in the Revisionsplan anticipated).

Kaltleiter the Heizboden and the antenna of the regulator may not be

transferred in the same Leerrohr.

The Bodenfühler of the regulator in the Fühlerschutzrohr introduce and

pay attention to it, that the end of the antenna in the Fühlerschutzrohr

at the following transfer in the area between two Heizleiter are used befindet.Sollte

an open Fühlerschutzrohr, so is to be locked this with a plug, that no

Fliesenkleber can penetrate itself into the reed.

The Fühleranschlussleitungen so transfer, that these cross the Heizleiter

neither nor touch. To

the content

10. Yield the Heizbodens:

With the Heizleiter after above the Heizmatte on the Verlegefäche, according

to the outline and Revisionsplan, yield. With a scissors the Stoffgewebe

can (attention: only the Stoffgewebe not the Heizleiter durchtrennen) are

cut through and are brought so the Heizmatte in the desired Verlegeform. Attention

important: Never the Heizleiter may be shortened the Heizmatte. The Heizleiter

at the durchtrennen the Textilgewebes do not damage.

At the durchtrennten place the Textilgewebes can be bent the Heizleiter

now carefully and are transferred parallel to the first path. The Heizleiter

however do not crack, which totals kleinst possible Biegeradius 20mm.

Also important:

The Heizbahnen the Heizmatte never one on the other transfer. Between

the Heizleitern must be at least a distance from 3cm available.

After this pattern the entire Verlegefläche is explained now with the

Heizmatte.

Attention warranty:

With a gauge the Ohmwert must be determined the Heizmatte (comparisons

with technical data) and in the Revisionsplan as well as in the Stromverteilung

are noted.

The Kaltleiter become, while the Heizmatte is pasted, in which Kleberbett

transfers to the Heizungsanschlussdose and introduced in the Heizungsanschlussdose

(the best in a separate Flexrohr, which leads from the wall - Estrichkante

in the Heizungsanschlussdose).

To

the content

11. Kleber for Heizmatte and Oberbelag:

| At the Verklebung the Heizmatte, the transfer of tiles as well as

as mechanical protection at Oberbelägen like carpets, PVC, cork, ect. if

Flexkleber suit, which are to maximum 80 C temperaturbeständig. |

1. Kleber for Heizmatten and ceramic disks (tiles) or Natursteinplatten:

PCI-Flexmörtel Specially - Fliesenkleber for balcony, terrace and underfloor

heating

Kleberbettdicke to maximum 5mm, from -20C to 80C, drying time approx.

4-5 hours.

Pci - Flexmörtel - Quickly Specially - Fliesenkleber for balcony, terrace

and underfloor heating

Kleberbettdicke to maximum 5mm, from -20C to 80C, drying time approx.

2-3 hours

or products of Knauf (ask you your Knauffachhändler)

2. Trittschutz at Oberbelägen, carpet, PVC, cork ect.

Around at the transfer of carpets, PVC, cork ect. a mechanical protection

to guarantee, must be covered the Heizmatte with a protective layer by

5 to 10 mm.

We recommend:

PCI-Periplan 10 to 10mm Schichtstärke

PCI-Periplan 20 to 20mm Schichtstärke

While the entire transfer examine with a gauge, whether the Heizmatte

is still conductive (Ohmwerte loudly technical data) To

the content

12th pasting the Heizmatten:

At the transfer of tiles and natural stones:

The instructions the Kleberherstellers are at the processing exact to

consider.

The Kleber is directed with a Zahnkelle (3-4 mm) on the floor. In this

Kleberbett the Heizmatte is inserted with the Heizleiter after above (smooth

page after below) and pressed with a Glättscheibe carefully. The durchgedrückten

Kleber carefully glattziehen. After that the upper side is covered the Heizmatte

once more with a layer of (Zahnspachtel 4-6 mm) Specially - Flexkleber, in

which directly the tiles or the natural stone is put. At the transfer on

it pay attention, that the Temperaturfühler comes between two Heizleitern

(loudly Revisionsplan) for the lying. The Kaltleiter just on the floor in

the Kleberbett to the Heizungsanschlussdose transfer and introduce through

a prepared Flexrohr in the Heizungsanschlussdose.

At the Verfugen of the tiles Flexfugenmasse use.

At the transfer of Oberbelägen like carpeting, PVC, cork, parquet:

After the Heizmatte was brought in described how above, and with a second

layer Specially - Flexkleber was covered, this mechanical protective layer

with the Glättscheibe must become cautious glattgezogen. If necessary

can be covered after 24 hours these dry Kleberfläche once more, with it

the surface smooth and even becomes (PCI-Periplan). The Verarbeitungshinweise

of the respective fillers - maker are exact to consider.

The preliminary treatment of the surface hangs from the further application

the special Kleber

z. B. from cork, PVC, parquet or carpeting from. An undercoat for the

consolidation, Haftverbesserung should be anticipated in any case as underground

- preliminary treatment.

At the earliest after three days the Oberbeläge can be begun according

to damps in the underground with the transfer.

Only for underfloor heating suitable Oberbeläge use.

To consider are following values for the warmth - Leitwerte:

- -Wert = 0,14 W/(m.K) at parquet maximum 16mm thickly

- -Wert = 0,09 W/(m.K) at carpeting maximum 20mm thickly

- -Wert = 0,08 W/(m.K) at cork maximum 10mm thickly

- -Wert = 0,23 W/(m.K) at PVC maximum 10mm thickly

- -Wert = 1,00 W/(m.K) at tiles maximum 30mm thickly

- -Wert = 1,00 W/(m.K) at natural stone maximum 30mm thickly

Attention:

The Heizleiter may not touch the Kaltleiter and do not cross also.

While the entire transfer examine the Ohmwerte and compare with the

first measurement...

At a damage the Heizmatte is recognized this immediately and the damaged

Heizmatte can be exchanged against a sound Heizmatte.

The room mark, that the Handwerkerkollegen are informed about the electric

underfloor heating. To

the content

13th electrics connection:

Only by an admitted expert the electric connection may be executed the

Heizmatte after the counting Vde - instructions and the Montageanweisung.

The Heizboden must be connected electrically so, that allpolig totals

the Kontaktöffnungsweite at least 3mm of the net. Ls - Switch, securities

and marksman in the distributor are suitable Trennvorrichtungen. The instructions

the local EVU are to be considered. Also a FI-Schutzschalter with 30 mA

should find in the Heizstromkreis application, to guarantee especially in

showers and baths the protection and the safety against dangerous Körperströme

(normally extend it from if the apartment is furnished or at least the Badezimmerverteilung,

from which the Heizstrom originates, with a Fi - protection). The Heizbodens

according to the circuit diagrams connect. To a flawless connection the Schutzleiters

(gelb/grün) pay attention. There can be connected several Heizböden to an

electronic thermostat. It in the technical data indicated maximum Schaltstrom

and/or Schaltleistung is to be considered.

To

the content

14. Circuit diagrams:

z. B: Leitungsverlegung:

After the work: After the works finished is must be placed in the Verteilerschrank

a Leistungsschild with entered Ohmwert at well visible place. In the Revisionsplan

these Verteilerplatz note and the user this installation and instruction

for the careful storage übergebenInbetriebnahme: After 48 hours the Heizmatte

can be heated the first times carefully (5 C/Tag)

Leitungsverdrahtung: EB 52521 Leitungsverdrahtung: EB 52527 / 28

To

the content

Technical data: Messprotokoll:

| Kind - No: |

Performance:

Watt/Stück |

Measured:

L x B in m |

Flat:

m2; |

Ohmwert /

Heizmatte

approx. |

Tension:

1/N/PE |

DreiMesswerte:

per rooms:

Ohm |

| Thermofloor 2000 S or Underfloor PV/5 160 watt /m2; |

| TF2S16/UPV160 |

160 watt |

3,3x0,3 |

1 |

330 Ohm |

230V/50Hz |

|

| TF2S26/UPV260 |

320 watt |

6,7x0,3 |

2 |

165 Ohm |

230V/50Hz |

|

| TF2S36/UPV360 |

480 watt |

10,0x0,3 |

3 |

110 Ohm |

230V/50Hz |

|

| TF2S46/UPV460 |

640 watt |

13,3x0,3 |

4 |

82 Ohm |

230V/50Hz |

|

| TF2S56/UPV480 |

800 watt |

16,7x0,3 |

5 |

66 Ohm |

230V/50Hz |

|

| Thermofloor 2000 S or Underfloor PV/5 130 watt /m2; |

| TF2S53/UPV530 |

650 watt |

10x0,5 |

5 |

81 Ohm |

230V/50Hz |

|

| TF2S63/UPV630 |

780 watt |

12x0,5 |

6 |

68 Ohm |

230V/50Hz |

|

| TF2S73/UPV730 |

910 watt |

14x0,5 |

7 |

58 Ohm |

230V/50Hz |

|

| TF2S83/UPV830 |

1040Watt |

16x0,5 |

8 |

51 Ohm |

230V/50Hz |

|

| TF2S93/UPV930 |

1170Watt |

18x0,5 |

9 |

45 Ohm |

230V/50Hz |

|

| Thermofloor 2000 S or Underfloor PV/5 100 watt /m2; |

| TF2S10/UPV100 |

100 watt |

2x0,5 |

1 |

530 Ohm |

230V/50Hz |

|

| TF2S20/UPV200 |

200 watt |

4x0,5 |

2 |

264 Ohm |

230V/50Hz |

|

| TF2S30/UPV300 |

300 watt |

6x0,5 |

3 |

176 Ohm |

230V/50Hz |

|

| TF2S40/UPV400 |

400 watt |

8x0,5 |

4 |

132 Ohm |

230V/50Hz |

|

| TF2S50/UPV500 |

500 watt |

10x0,5 |

5 |

106 Ohm |

230V/50Hz |

|

| TF2S60/UPV600 |

600 watt |

12x0,5 |

6 |

88 Ohm |

230V/50Hz |

|

| Thermofloor S 160 watt /m2; |

| TFS116 |

160 watt |

2x0,5 |

1 |

330 Ohm |

230V/50Hz |

|

| TFS216 |

320 watt |

4x0,5 |

2 |

165 Ohm |

230V/50Hz |

|

| TFS316 |

480 watt |

6x0,5 |

3 |

110 Ohm |

230V/50Hz |

|

| TFS416 |

640 watt |

8x0,5 |

4 |

82 Ohm |

230V/50Hz |

|

| TFS516 |

800Watt |

10x0,5 |

5 |

66 Ohm |

230V/50Hz |

|

| TFS616 |

960Watt |

12x0,5 |

6 |

55 Ohm |

230V/50Hz |

|

Technical data:Eberle 52527 / 28

Back

Back

Bestellblatt:

To the order you click Produktnamen in the dunkelblauen

Anzeigefeld and choose on the right the Produktkategorie from choose you

the products through it - " orders " - Button. The products will print then

automatically in the Auswahlmenü - " Faxbestellung " - on the left below

transfer that you from and then fax or can send with the post.

| Kind - No: |

Performance:

Watt/Stück |

Measured:

Long x B

in m |

Flat:

m2; |

ordered piece: |

Preis:DM |

Gesamt:DM |

Thermofloor 2000 S or Underfloor PV 160 watt /m2; width 30 cm

| TF2S16/UPV160 |

160 watt |

3,3x0,3 |

1m2; |

|

|

|

| TF2S26/UPV260 |

320 watt |

6,7x0,3 |

2m2; |

|

|

|

| TF2S36/UPV360 |

480 watt |

10,0x0,3 |

3m2; |

|

|

|

| TF2S46/UPV460 |

640 watt |

13,3x0,3 |

4m2; |

|

|

|

|

800 watt |

16,7x0,3 |

5 m2; |

|

|

|

Thermofloor 2000 S or Underfloor PV 130 watt /m2; width 50 cm

| TF2S53/UPV530 |

650 watt |

10x0,5 |

5m2; |

|

|

|

| TF2S63/UPV630 |

780 watt |

12x0,5 |

6m2; |

|

|

|

| TF2S73/UPV730 |

910 watt |

14x0,5 |

7m2; |

|

|

|

| TF2S83/UPV830 |

1040Watt |

16x0,5 |

8m2; |

|

|

|

| TF2S93/UPV930 |

1170Watt |

18x0,5 |

9m2; |

|

|

|

Thermofloor 2000 S or Underfloor PV 100 watt /m2; width 50 cm

| TF2S10/UPV100 |

100 watt |

2x0,5 |

1m2; |

|

|

|

| TF2S20/UPV200 |

200 watt |

4x0,5 |

2m2; |

|

|

|

| TF2S30/UPV300 |

300 watt |

6x0,5 |

3m2; |

|

|

|

| TF2S40/UPV400 |

400 watt |

8x0,5 |

4m2; |

|

|

|

| TF2S50/UPV500 |

500 watt |

10x0,5 |

5m2; |

|

|

|

| TF2S60/UPV600 |

600 watt |

12x0,5 |

6m2; |

|

|

|

Thermofloor S 160 watt /m2; width 50 cm

| TFS1 |

160 watt |

2x0,5 |

1m2; |

|

|

|

| TFS2 |

320 watt |

4x0,5 |

2m2; |

|

|

|

| TFS3 |

480 watt |

6x0,5 |

3m2; |

|

|

|

| TFS4 |

640 watt |

8x0,5 |

4m2; |

|

|

|

| TFS5 |

800Watt |

10x0,5 |

5m2; |

|

|

|

| TFS6 |

960Watt |

12x0,5 |

6m2; |

|

|

|

Regulators & Installationsset for Thermofloor S & 2000S as well

as Underfloor PV

| EB 52527 |

El. -Temperaturregler with Bodenfühler

Tageszeitschaltuhr |

|

|

|

| EB 52528 |

El - Thermostat with Bodenfühler

Wochenzeitschaltuhr |

|

|

|

| EB 52521 |

El - Thermostat with Bodenfühler |

|

|

|

| Instset |

UP.Anschlussdose 100x100

Fühlerschutzrohr 1m & 2x Flexrohr |

|

|

|

Address or stamps with signature:

Endpreis: |

Fliesenh

Electrical

underfloor heating

Electrical

undertile heating

Electrical

thin-bed underfloor undertile heating

Electric under

floor heating

Electric under

tile heating

Electric thin-bed

under floor heating under tile heating

eizung Elektroheizung

electric Wärmeboden floor heating system Heizboden Heizmatten heat warm

bath kitchen Kinderzimmer tiles stone floor cold feet Trockenboden Altbausanierung

Ferkelaufzucht Fliesenkleber Eberle Tekmar Termostat

electric underfloor heating Fliesenheizung

floor heating system Heizmatten Wärmeboden Badheizung Temperierung Speicherheizung

bath tiles Elektroheizung Flächenheizung Wintergarten frostschutz Eberle

Heizboden Dünnbrettheizmatten Altbausanierung Trockenboden warmth cold feet

Fuesse parquet Fliesenkleber Bodentemperierelemente 48V renovating Zeitschaltuhr

Fliese

Look at!

Underfloor Heating

Overview of FH, FH-TWIN THERMOFLOOR and WARMTOUCH

The high quality heating mats:

|

Warmtouch WT PV-S-10N

Woven fabric, height 3mm

|

ThermofloorS

Woven fabric, height 3.5mm

|

|

FH-TWIN

Reinforced fabric, height 2mm FH-TWIN

2.5mm

|

Warmtouch WT PV-3L-5N

Woven fabric, height 3mm

|

What are FH, FH-TWIN, Thermofloor and

Warmtouch?

The heating wire is wound into a woven or a reinforced

fabric.

The heating wire has a diameter of only 3 or 4 mm, is

moisture-resistant, totally insulated and is sheathed in a protective wire

mesh; it is made from a high quality resistance alloy.

4m long PTC resistor connection leads (neutral/PE, phase,

PE) made from tin-plated copper are attached at the beginning and end of

each heating mat.

The connecting sleeves are absolutely watertight, strain

relieved and can also withstand high temperatures (80°C).

The heating mats can be laid flat on the floor base with

no bulges as a result of the highly flexible fabric weave.

The heating mats are available in two different lengths,

0.3m and 0.5m, suitable for different floor sizes.

The 120 Watt/m² version is designed for heating carpeted,

PVC or parquet floors, whereas the 160 Watt/m² or 120 Watt/m² version is

suitable for tiles and stone floor coverings. 160 Watt/m² or 200 Watt/m²

heating mats are designed for use in conservatories and in the bathroom.

120 Watt/m² heating mats are most appropriate for taking

the chill evenly off larger living areas (or e.g. for Fermacell, Soporo,

Majestic or Wedi boards).

Page 2

Laying examples:

The heating mats can be laid on any smooth underfloor

surface such as concrete, moisture-resistant chipboard or dryfloor covering

(as often used in the redevelopment of older buildings).

Follow the instructions for positioning and laying ceramic

tiles and boards on chipboard issued by the German Tile Industry Guild

(or equivalent).

It should be noted that even hot or poured asphalt can

only withstand temperatures of 80°C.

The heating elements are very flexible when laying. The

wound pattern of the heating wires means that there is a wide variety of

laying possibilities. Maximum adaptation is possible for the most diverse

range of floor layouts (with two laying widths: 0.3 and 0.5 m).

By cutting the fabric weave with a pair of household scissors,

the heating elements can easily be adapted to the required outline as shown

in the laying plan.

The sensor protection tube now needs to be laid so that

the sensor can be fed from the heating connection box into the protection

tube and laid beneath the heated area.

After this you can start to lay the cut-to-size heating

mats on the dry, smooth and dust-free ground using a heat-resistant (80°C)

tile adhesive from Knauf or PCI.

Press the heating mat with heating wire into the adhesive,

ensuring that the heating wires do not touch or overlap.

It is extremely important that the heating mat is applied

evenly without trapping any air beneath it. Lay the decking surface using

tile adhesive, smoothing it down to provide mechanical protection when

laying cork, PVC etc.

Page 3

Electrical connections in the UP heating connection box:

The electrical fitting of the underfloor heating should

be undertaken by a certified electrician in accordance with the current

VDE regulations and these fitting instructions.

The volume resistance (conductivity) of the heating mat

should be measured continuously during the entire fitting procedure.

The continuous measurement of the volume resistance ensures

that any damage to the heating mat is detected immediately and that the

damaged item can then be exchanged for a fully functioning one.

The Ohm value of each mat should be entered in the room

layout plan and on the rating plate (junction box).

The heating circuit should also feature a 30 mA circuit

breaker, especially in showers and bathrooms, to ensure protection and

safety against dangerous electrical shocks (unless the apartment as a whole,

or at least the bathroom junction box from where the heating current originates,

is fitted with a circuit breaker).

The connection leads of the heating mat and the temperature

sensor routed into the embedded junction box should be connected as per

the circuit diagram below. Make sure the PE wire (yellow/green) is properly

connected.

Multiple heating mats should only be connected in parallel.

Temperature regulation:

EB 52531

The floor temperature is measured by the NTC sensor and

regulated by means of the EB 52531 electronic thermostat. The sensor

of the thermostat is laid in the floor beneath the heating wires in the sensor

protection tube, directly beneath the heating layer. The floor temperature

can be set on the thermostat to meet your personal requirements

and those of the particular room (living room or bathroom).

EB EASY 3 ft EB 52535 OJ OTN & OCC2/D2

Timed operation by the EASY 3 ft (daily timer

switching) or EB 52535, or OCC2/D2 (daily and weekly timer switching)

timer thermostats is highly economical, yet there is no loss of

comfort or convenience. The electronic thermostat should be set so

that it automatically switches on the heating 30 minutes before the

room is to be used. The unit switches off again automatically during

or after use, preventing any unnecessary heating. You can also switch

the heating on and off outside the times set on the timer, of course.

Page 4

|

Example of cable laying:

|

Example of wiring:

|

Full instructions for assembly and operating are enclosed with each delivery.

|

Applications:

* Tiled stove heating

* Bathroom, kitchen, nursery

* Selling areas, e.g. butchers

* Offices

* Low raised floor height

* Aesthetic reasons (no radiators)

* Renovation of old buildings (e.g. dry floors)

* Partial floor heating for seating area

* Conservatory frost protection

|

Advantages:

* Quick and easy to lay

* Rapid heating to desired temperature (bathroom in morning)

* Controlled by timer thermostat

* Extremely thin heating mats, 3 mm and 4 mm thick

* Safe, low-cost, maintenance-free

* Conforms to international standards

* Warm feet, cool head

* Pleasant house temperature

* Lower temperature possible through high heat radiation

|

Please read carefully - important for understanding floor heating:

Heating and electricity consumption

If 160 Watt/m² floor heating is fitted in a room with floor tiles, the

heating only consumes 160 Watt/m² during the warm-up period, e.g. from

18°C to the target floor temperature of 24°C. At 160 Watt/m² rating this

is of course correspondingly faster than 120 Watt/m² - and you save time

in the warm-up phase. Subsequently the floor heating, i.e. from the surface

of the floor tiles, only releases approx. 10 Watt/m² heating power into

the room for each degree Celsius warmer than the room itself. Roughly half

of the heat is released into the room in the form of infrared heat, i.e.

radiant heat.

If the temperature in the room is 22°C and the floor is 24°C, the floor

heating would then only release 20 Watt/m² into the room. If the room is

warmed e.g. by the sun to 24°C, the floor heating will release no more heat

at all into the room and therefore not consume any more electricity. This

is the self-regulation effect of floor heating. The high percentage of radiant

heat in floor heating means that the room temperature can easily be turned

down by several degrees to e.g. 20°C, and it will still be perceived as pleasantly

warm. A floor temperature of 21°C is felt as warm (the emphasis here is

on the feeling of comfort created by floor heating - the prime source of

heating is e.g. radiators). In this case the floor heating would only release

10 Watt/m² into the room.

With a heating area of e.g. 10 m² and a rating of 10 Watt/m² this would

result in electricity costs of 15 cents for 10 hours at a price of 15 cents/kwh.

This assumes adequate thermal insulation beneath the floor base.

In an extreme case, a 160 Watt/m² floor heating system would heat a room

from 20°C to 36°C (i.e. one degree per 10 Watts) if it were not limited

by the thermostat to approx. 28-29°C.

If the floor plate is thick enough, e.g. 8cm (e.g. heating base from Knauf)

and if the customer has access to suitably low-cost storage heating electricity,

it is also possible to heat an entire apartment or individual rooms with

night storage underfloor heating. The investment costs are relatively low.

If the intention is to use the underfloor system as the main source of heating,

it is important to use night storage current or, better still, to change

to a night-heating tariff.

The consumption costs are …, i.e. one litre of heating oil provides 10kW/h

of chemical energy although only 80-90% is actually used as heat in the

flat (boiler, radiation and chimney losses). In the case of electricity,

however, 100% is given up to the floor surface. And there are no costs for

chimney sweeps, boiler maintenance or fume emission measurement.

nh

Electrical

underfloor heating

Electrical

undertile heating

Electrical

thin-bed underfloor undertile heating

Electric under

floor heating

Electric under

tile heating

Electric thin-bed

under floor heating under tile heating

Easy Electric thin-bed

under floor heating under tile heating

UNDERFLOOR HEATING UNDER

TILE HEATING UNDERFLOOR TILE